Introduction

Bone grafts are used clinically in the treatment of many forms of

bone tissue defect (e.g. fracture alignment/non-union, critical-sized defects,

maxillo-facial surgery and spinal fusion). They actively promote healing and new

bone formation (osteogenesis) using a biocompatible, osteoconductive and

osteoinductive graft structure that provides mechanical support and promotes

osteogenesis. Historically, the gold standard has been either autografts

(patient’s own tissue) or allografts (donor tissue).

Whilst autografts are still widely used, drawbacks such as donor

site morbidity are shifting the market rapidly toward the use of allografts and

synthetic bone graft substitutes. However, due to the inherent drawbacks of

these materials, development of an ideal bone graft substitute made from

materials already found within the body is paramount.

Bone grafts are second only to blood transfusions on the list of

transplanted materials worldwide. The total U.S. bone graft and bone

graft substitutes market revenues were $ 1.3 billion in 2006. This is expected

to reach $ 3.3 billion in 2013 with the compound annual growth rate (CAGR) from

2006 to 2013 expected to be 13.8%. The total European bone graft substitute

market alone is expected to reach $120m by 2010.

Technology

The RCSI bone graft substitute, HydroxyColl, combines the two main

constituents of bone tissue, namely hydroxyapatite and type I collagen, in the

form of a three dimensional construct that possesses the requisite intrinsic

mechanical strength, architecture and biocompatibility for successful use as a

commercial bone graft substitute, improving on currently available products.

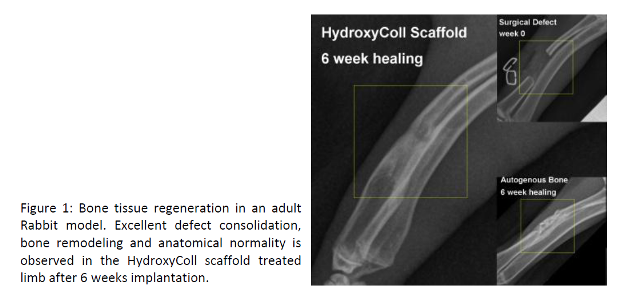

The development of HydroxyColl has culminated in a number of

successful pre-clinical studies, highlighting the excellent regenerative

potential of this biodegradable bone graft substitute (Fig. 1).

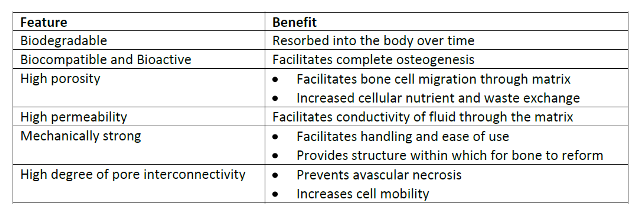

The RCSI team has developed a novel proprietary

collagen/hydroxyapatite (CHA) based technology that has the high levels of

permeability, porosity, and pore interconnectivity required to ensure scaffold

viability and promote osteogenesis in vivo while offering variable mean

pore size for cell-specific biological activity. In summary, this technology

offers a 3-D scaffold with the prerequisite mechanical, biocompatible and

bioactive characteristics for successful use in vivo.

Applications

A global ageing population coupled with increasing prevalence of

obesity and sedentary lifestyles calls for increased innovation and advancements

in implant design. As much as 60% of all injury-related physician visits are

linked to the musculoskeletal system. New technologies are currently in

development that could drastically change the nature of orthopaedic surgery

creating key opportunities for synthetic, manufactured products.

There is an unmet need for a successful bioactive, load bearing,

bone substitute material that promotes osteogenesis in vivo. This is

something of a ‘holy grail’ in the medical device industry.

Advantages

This novel CHA based technology will offer a real alternative not

only to existing commercially available synthetic products but also to auto and

allografts.

A significant increase in the scaffold compressive strength,

as well as its permeability (an important determinant of in vivo

viability) has been achieved with no detrimental effect to either the

scaffold porosity or biocompatibility.

HydroxyColl

is a biomimetic and biodegradable alternative to autogenous bone and a viable

and cost effective bone regeneration aid for clinical

use.

Contacts:

Dr Aoife Gallagher, RCSI Technology Transfer, 123 St Stephen’s

Green, Dublin 2, Ireland.

Email: aoifegallagher1@rcsi.ie. Tel: +353 1 4022394

Dr Liz Moran, Enterprise Ireland, East Point Business Park, Dublin

3. Email: liz.moran@enterprise-ireland.com.

Principle Investigator:

Prof. Fergal J

O’Brien & Dr. John Gleeson, Dept. of Anatomy, Royal College of Surgeons, 123

St Stephen’s Green, Dublin 2, Ireland. Email: fjobrien@rcsi.ie or

johngleeson@rcsi.ie